StatPort is a widely used Industrial Grade product that delivers IT – OT convergence through the use of Machine Learning, Services Oriented Architecture, Big Data and Meta Data.

Machine Learning is used to parse data from different data sources into a Data Framework, Services are used to transport the data from the Edge to the Big Data backend and, Meta Data is used to translate the data in real time from one structure to another.

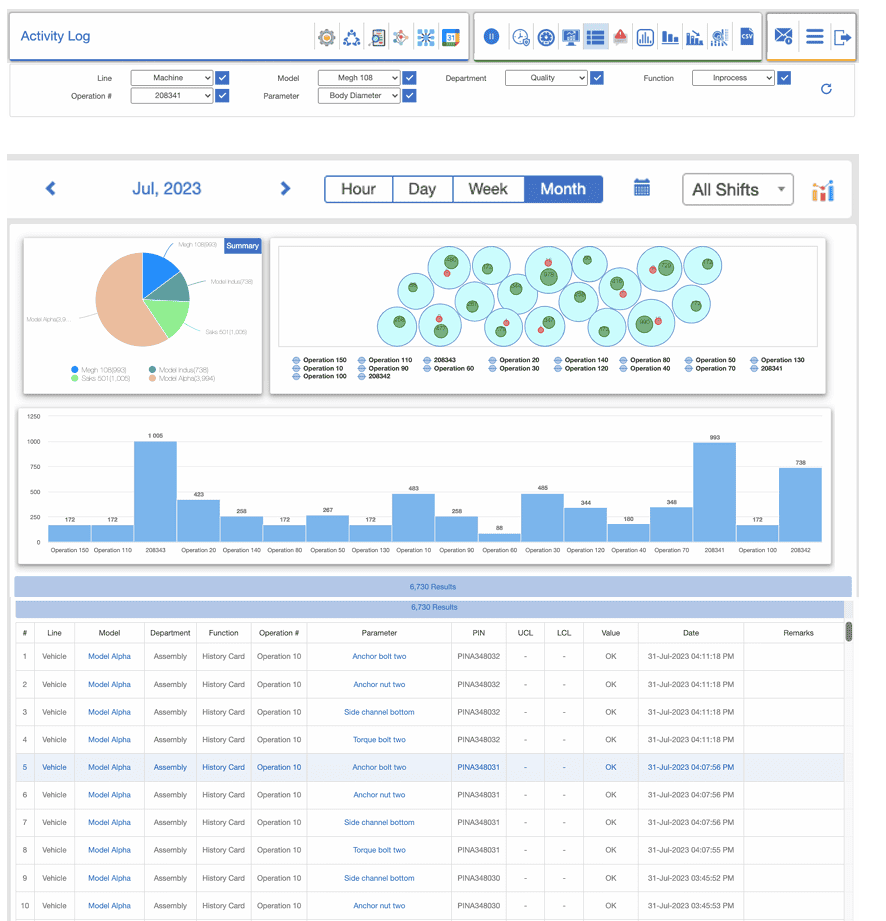

StatPort integrates data across sources into ‘easy to use’ industrial grade data logs.

From the data logs, in real time, it delivers monitoring for abnormal events, analytics, dashboards and workflows.

Data is transported and translated to actionable insights, so that you can focus on operations and can deliver outcomes.

StatPort delivers real time Visibility of Operations and significant improvements in Productivity, Quality and Uptime. It also delivers benefits in terms of Compliance, Traceability and Sustainability.

With StatPort, you replace Paper with Smart Systems and, upskill your workforce to be efficient in this new age of manufacturing.

StatPort has been designed and built through extensive assessments of manufacturing value streams. We have built product features by listening to real world problem statements and objectives. Many features are based on principles of Total Quality Management & Total Productive Maintenance.

Across these customer locations StatPort has logged more than 75 million data points:

Ashok Leyland, ACWA Automatics, Ather Energy, ABI Showatech (Brakes India), Birla Cements, Ceat Tyres, Carborundum Abrasives, CUMI Industrial Ceramics, Dharani Pumps – Perfect Engineers, Hyundai Motors, Indian Metal One Sheet Processing, Mangal Industries – Amar Raja, Pidilite, Sansera Engineering & Surin Automotive.

Real Time Visibility

- High speed data acquisition across sources, translation & delivery

- Real time visibility into operations

- Defect detection and workflow for rework & quality approvals

- One touch – Drill down into operations, source data

- Traceability search – Batch – Product data trail at your finger tips

Total Quality Management

- Configurable Statistical Quality Control with Machine Learning

- Scheduling, sampling, operational definitions, data types

- Real time Cp, Cpk – Statistical Capability (Six Sigma)

- Dashboard for Daily Works Management (Percolation)

- CAPA module for Problem Solving with monitoring for Sustainability

True Productivity

- IT & OT convergence to monitor operations & sequences

- Translation of material positions into cycle time & waiting time

- Instant identification of production losses, bottle neck points

- Andon calls – across functions, bringing stakeholders together

- Wizard for review and resolution of production losses (TPM)

Workforce & Processes

- Author blueprints by bringing together data across operations

- Orchestrate routines – to emulate human monitoring

- Bind SOPs and Poka Yoke into data points

- Monitor operations for adherence & compliance

- From person - person to institutional process centricity

Production

Industry 4.0 is often associated with Condition Monitoring and Predictive Maintenance – to reduce downtimes. However,

with experience we realise, that machine uptime does not equal line effectiveness. Factories with 85% utilisation of machines

often achieve 65% of throughput, to deliver outcomes, you need to go beyond machines, and look at the entire value stream.

Smart Quality

StatPort uses Machine Learning (Parsers) to integrate with a wide variety of measurement – monitoring systems including CMM, SCADA, Electronic Multi Gages, Calipers, Micrometers and more. StatPort supports Modbus, MQTT and Ethernet protocols to access data from measurement systems in real time.

You can also use StatPort for Digital Transformation of your Control Plans, and replace paper logs and check sheets with Smart Apps. The Apps will enforce your Control Plans and ensure that your manual inspections are timely and reliable.

Traceability

Retrieving documents or data from the Archive to respond to a customer complaint – is a time consuming and effort intensive activities. With StatPort, you can search for a retrieve data from the archive within seconds. You can prove adherence to processes and generate a traceability report to respond to customer complaints. In Process manufacturing, you can use Traceability to study correlation across process and output characteristics.

Workflow

Convergence in StatPort integrates data sources, derive meta (translated data), bring up KPIs and create system based monitoring. For example you can create a convergence of internal events from the control system of a machine, along with external events punched in by the Operator to bring up a single process document.

You can replicate human oversight with a data – driven system based monitoring.

Managing Teams

As a StatPort user you get Actionable Insights from Machine Learning and Monitoring. A process characteristic outside acceptable limits, a dimensional measurement showing instability, production losses in cycles, time lost in setup and changeover, machine condition, tool life are all examples of Action Insights from StatPort.

With the Activity Module, you can assign your best minds to study the problems and deliver improvements. Assigned activities can be tracked for progress, completion and satisfactory outcomes. These features form basis for workforce analytics and performance management. APIs from StatPort can be used to deliver performance data to your HRMS or ERP.

Systems & Services

As an Industrial Grade product, conceptualised, built and tested extensively on the shop floor, StatPort has a number of features that make it Easy to Operate, Respond to Change and Support Growth. Systems & Services deliver:

- Monitoring of the ‘IoT Edge’ to ensure that data streams are on time, in the right structure

- Ensure that network connectivity and services are performing at acceptable speed

- Features to modify data models, change chart types, add users, moderate user acc

Critical Success Factors

Custom Configurations

Our digital platforms are lead by your business and process requirements. We make technology adapt to your business and not the other way around. Our platforms are designed to be configured to your needs.

Online Support

We deliver proactive customer engagmenet solutions bundled with our platform offerings. Our customer engagement consultants will hand hold your team on a regular basis and deliver optimisations for better results.

Specialty Modules

CMM integration, Visual inspection, Audit Module, Assembly inspections, Gage Integration, CAPA, Online Cpk, Attribute Charts, Drill down dashboards, Alerts & Escalations, Deviation Management, Email Digests, Document Management, Barcode, QR Code, RFID integration, Workflow, Traceability, OEE, Maintenance

Scalable performance

Our annual subscription models offer a unique Service Level Agreement that covers platform performance. As part of on going subscription we will fine tune your Big Data archive to ensure that you continue to get consistent performance and results from the platform.

Big Data vs Total Cost of Ownership

- Big Data, Cloud Architecture are often closely associated with IoT and Analytics. In practical terms, you could be thinking about costs. Big Data in StatPort is based on Mongo DB Community Edition – bringing you 70% savings in terms of long-term data storage compared to traditional RDBMS databases.

- While StatPort is built on a 100% services-oriented architecture (Restful – Web API), all our services are native to our product. We do not incur cloud services costs and, in turn transfer the advantage of reduced Total Cost of Ownership to you. Our engagement model gives you 5-year visibility and commitment.