Drive Success with StatPort

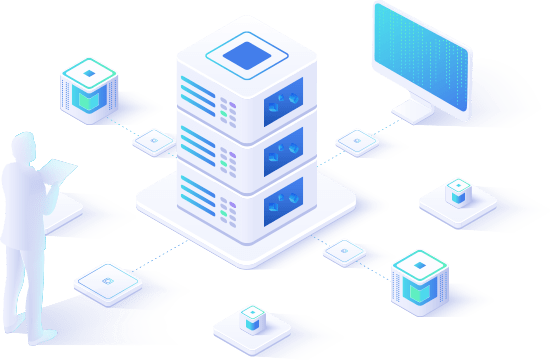

Integrate digital sources across functions, locations, levels and stages, Digitalise process artefacts, Harmonise all data sets into a common language – Convergence that brings sustainable bottom line impact.

We deliver data convergence across Machine Interfaces: PLC & SCADA, OPC-UA, MT Connect, Sensors, Transmitters Measurement Systems: Digital Gages, CMM & Vision Systems Code: Barcodes, QR Codes, RFID signals Software Interfaces: APIs, RESTful, SOAP, Web services and more.

Why Choose People Statport

StatPort is built on a strong Master Data Management Framework and Service Oriented Architecture with Big Data backend with IoT / Edge integration to deliver Statistical Process Control, Analytics & Automation and Smart Factory outcomes. StatPort delivers Production Monitoring – OLE / OEE, Enterprise Wide Quality Control, Digital Audits, Preventive & Predictive Maintenance.

Track Record

We drive success by adopting a horizontal approach to Digital Transformation.

Product

Industry 4.0 initiatives are dominated by custom services and products that focus on one function.

Customer Engagement

‘Discovery’ in Digital Transformation is vital to success and our team wears hard hats and invests time in your shop floors.

Track Record

We drive success by adopting a horizontal approach to Digital Transformation. Our convergence works across different functions of manufacturing and supports all popular data structures and formats in the manufacturing shop floor. Our implementations are governed by your problems rather than our product features.

Product

Industry 4.0 initiatives are dominated by custom services and products that focus on one function: such as condition monitoring. StatPort is built as a product with: Configurable Master Data Management, Data Models, Analytics Models, Service Oriented Architecture, Mobility – Apps and, Workflow Automation. This means, risk mitigation and shorter implementation life cycles.

Customer Engagement

‘Discovery’ in Digital Transformation is vital to success and our team wears hard hats and invests time in your shop floors. We work with you to identify data sources, build master frameworks and document your processes for transformation. We have a well-tuned model for end user training and have a 100% track record in implementation success.

Process Consulting + Go Digital

We have customised start points for your transformation

Process Ready: Consulting to build your Quality Management Framework.

Framework Ready: Start Digital Transformation.

100+ Companies are Using Statport

Tier 1 Components

"Our requirements were unique as a foundry, heat treatment and machining shop delivering 1000+ components. As a Tier 1 Export Oriented Unit with Aeronautical aspirations we had very specific expectations from our Digital Transformation. Specifically building the initial framework across all our stages of manufacturing for large number of components was quite challenging. PQSI Digital delivered to our requirements and, today their Smart TV dashboard welcomes customers with live analytics and insights"

Tier 1 Fabrication, Bangalore

Director"PQSI Digital’s approach and cost efficiencies gave us the confidence to go for Digital Transformation simultaneously across all our locations. In the fabrications space, data volumes are high and the need for visual inspections were very well met by their mobile apps. We are now completing inspections of large components within 2 minutes on an intuitive touch interface."

MSME, SIPCOT, Chennai

Director"As an SME we were apprehensive about Digital Transformation, especially about investments in this uncertain climate. PQSI Digital supported us with a monthly subscription model that cost much less than a full time resource and gave us the same quality of a large enterprise. We have a cellular manufacturing model and our value stream needs to be agile and elastic. We were surprise how StatPort easily fit our needs without customisations"

Tyre Manufacturer

"StatPort has accelerated the Statistical Process Control journey and continued to deliver success with excellent upgrades and support during the pandemic. We are definitely considering pan India implementations"

Leading Truck & Bus OEM

GM - Manufacturing Quality"StatPort is at the heart of our migration to BS VI standards, we have made significant investments in manufacturing infrastructure, specifically in fixtures. StatPort helps us with live monitoring across a multitude of digital sources and gives us statistical validation of our improved capabilities”

Global Leader, Industrial Ceramics

DGM"We are amazed that we could complete implementation of StatPort entirely online given lockdown and restrictions around the pandemic. With StatPort we have Workflow Automation and Remote Monitoring that saves 2500 management hours in addition to driving our Line Effectiveness month on month – we are confident of recovering 10x of our investments in Digital Transformation in the 1st year itself"